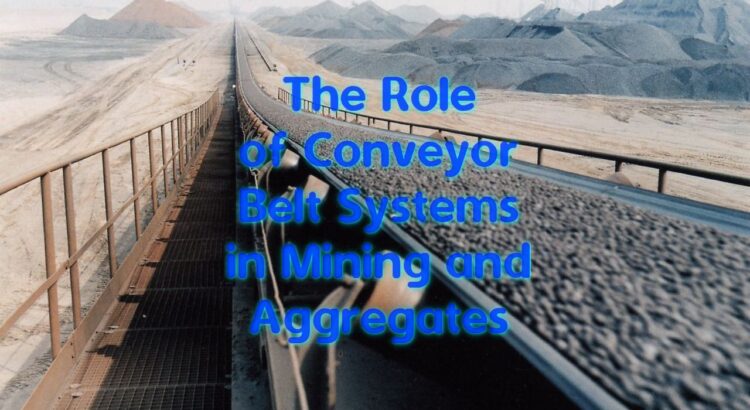

Conveyor belt systems are used extensively in the mining and aggregates industry to transport a wide range of materials, from ores and minerals to sand and gravel. These systems play a critical role in the efficiency and productivity of mining and aggregates operations, enabling materials to be moved quickly and efficiently throughout the site. In this article, we will explore the role of conveyor belt systems in mining and aggregates.

Transporting Raw Materials

One of the primary functions of conveyor belt systems in mining and aggregates is transporting raw materials. In mining, conveyor belts are used to transport ore and minerals from the mine to the processing plant or stockpile. The belts can also be used to transport waste materials, such as overburden, from the mine to disposal sites.

Conveyor manufacturers in Australia produce conveyor belts that are used to transport materials such as sand, gravel, and crushed stone from the quarry to processing plants, stockpiles, or loading facilities. The belts can also be used to transport materials between different processing stages, such as from the crushing plant to the screening plant.

Efficient and Cost-Effective Material Handling

Conveyor belt systems offer several advantages over other forms of material handling, such as trucks or haulage equipment. One of the primary advantages is that they are more efficient, allowing materials to be transported quickly and continuously. This can help to reduce the time and labor required for material handling, which can result in significant cost savings.

Conveyor belts also offer greater flexibility than other forms of material handling. They can be designed to accommodate different materials and loads and can be configured to follow different routes and angles. This can help to optimize the flow of materials through the site, improving efficiency and reducing bottlenecks.

Reducing Environmental Impact

Conveyor belt systems can also help to reduce the environmental impact of mining and aggregate operations. By transporting materials more efficiently and with less fuel consumption than trucks or haulage equipment, conveyor belts can help to reduce greenhouse gas emissions and other pollutants.

In addition, conveyor belts can help to reduce the impact of mining and aggregate operations on local ecosystems. By reducing the need for trucks or haulage equipment, conveyor belts can help to reduce noise and dust pollution, as well as the risk of soil erosion and damage to local vegetation.

Safety and Maintenance

Safety is a top priority in mining and aggregate operations, and conveyor belt systems can play a critical role in ensuring the safety of workers. By reducing the need for trucks or haulage equipment, conveyor belts can help to reduce the risk of accidents and injuries associated with these types of equipment.

In addition, conveyor belt systems can be designed with safety features such as emergency stop buttons and safety barriers to further reduce the risk of accidents. Regular maintenance and inspections of conveyor belt systems are also essential to ensure the safety of workers and the continued efficiency of the system.

Conclusion

In conclusion, conveyor belt systems play a critical role in the efficiency, productivity, and safety of mining and aggregates operations. By transporting materials quickly and efficiently, conveyor belts can help to reduce the time and labor required for material handling while improving the flow of materials through the site. They can also help to reduce the environmental impact of mining and aggregates operations and improve safety for workers. As such, conveyor belt systems are an essential component of modern mining and aggregates operations, enabling these industries to operate more efficiently, safely, and sustainably.